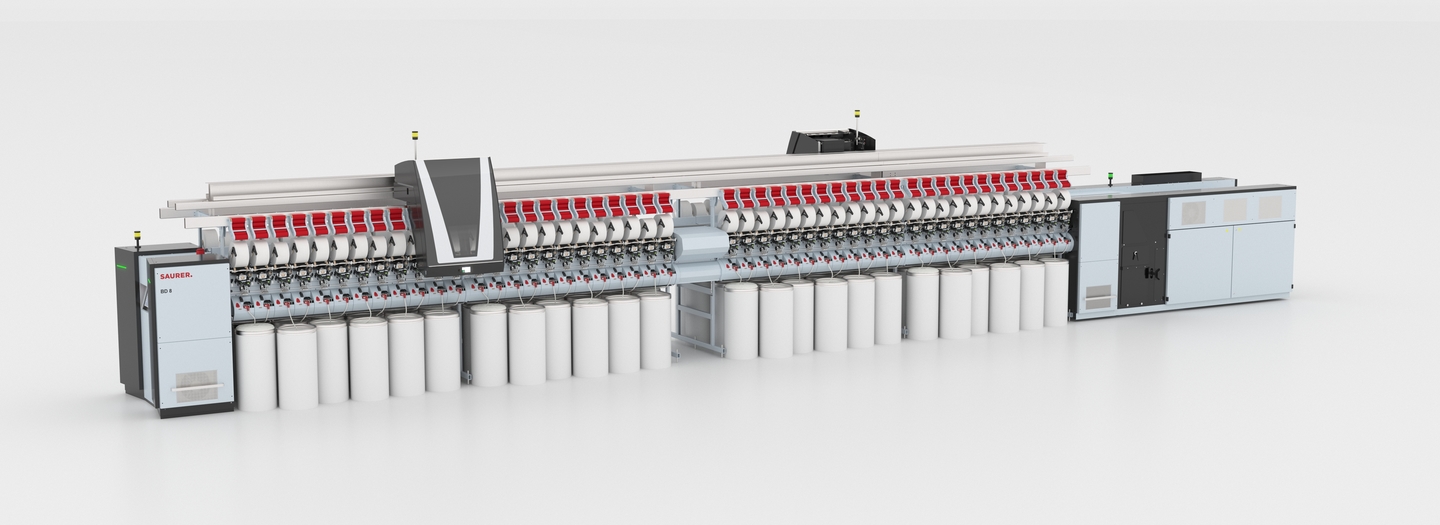

Automation has become a vital part of the textile industry, driving efficiency and maintaining productivity in the face of labor shortages. The Saurer BD 8 semi-automatic rotor spinning machine is designed to meet these needs by offering a practical and efficient solution for spinning mills. Equipped with a new, advanced doffer unit, this machine is engineered to enhance operations and streamline workflows.

One of the key features of the BD 8 is its automatic package doffing unit. This doffer unit greatly reduces operator workload by changing full yarn packages in just 10 seconds, without interrupting the spinning process. The machine can be equipped with up to four of these doffers, allowing seamless handling of large production volumes. It supports large packages up to 320 mm in length and 5 kg in weight, with automatic doffing triggered for all packages within the defined tolerance range. The yarn reserve is adjustable to maintain consistent quality and production continuity.

Beyond its primary function, the doffer unit also serves as a blowing device when package changing is not required, enhancing the machine’s operational flexibility. This dual capability helps keep the spinning units clean and running smoothly. The doffer unit can be installed on the BD 8 as well as the older BD 7, offering an upgrade path to mills looking to automate and improve efficiency.

The BD 8 offers more than automation. It combines ergonomic design and energy-saving technologies like the Twinsuction system, which reduces vacuum requirements by about 40% and lowers energy use by up to 10%. With up to 600 spindle positions and take-up speeds reaching 230 meters per minute, it delivers strong productivity while maintaining premium package quality.

This machine is versatile enough to handle various yarn types, including coarse yarns and recycled fibers, making it a reliable choice for mills adapting to raw material fluctuations and the circular economy. The BD 8 also features smart operation aids such as digital piecing technology for superior piecing reliability and an intuitive touchscreen interface for easy control.

For spinning operations aiming for improved productivity, reduced labor demands, and consistent yarn quality, the Saurer BD 8 with its automatic doffing unit stands as an effective solution. The capability to change packages quickly and manage large yarn packages automatically means less downtime and more continuous production, which is critical in today’s competitive textile market.