As the global apparel industry grapples with rising labor costs, shrinking lead times, and increasing pressure for compliance and quality consistency, robotic sewing has emerged as a futuristic yet pragmatic solution. From sew-bots to semi-automated modules, the conversation has shifted from “Will this work?” to “Where does it work best?”

The Promise of Robotic Sewing

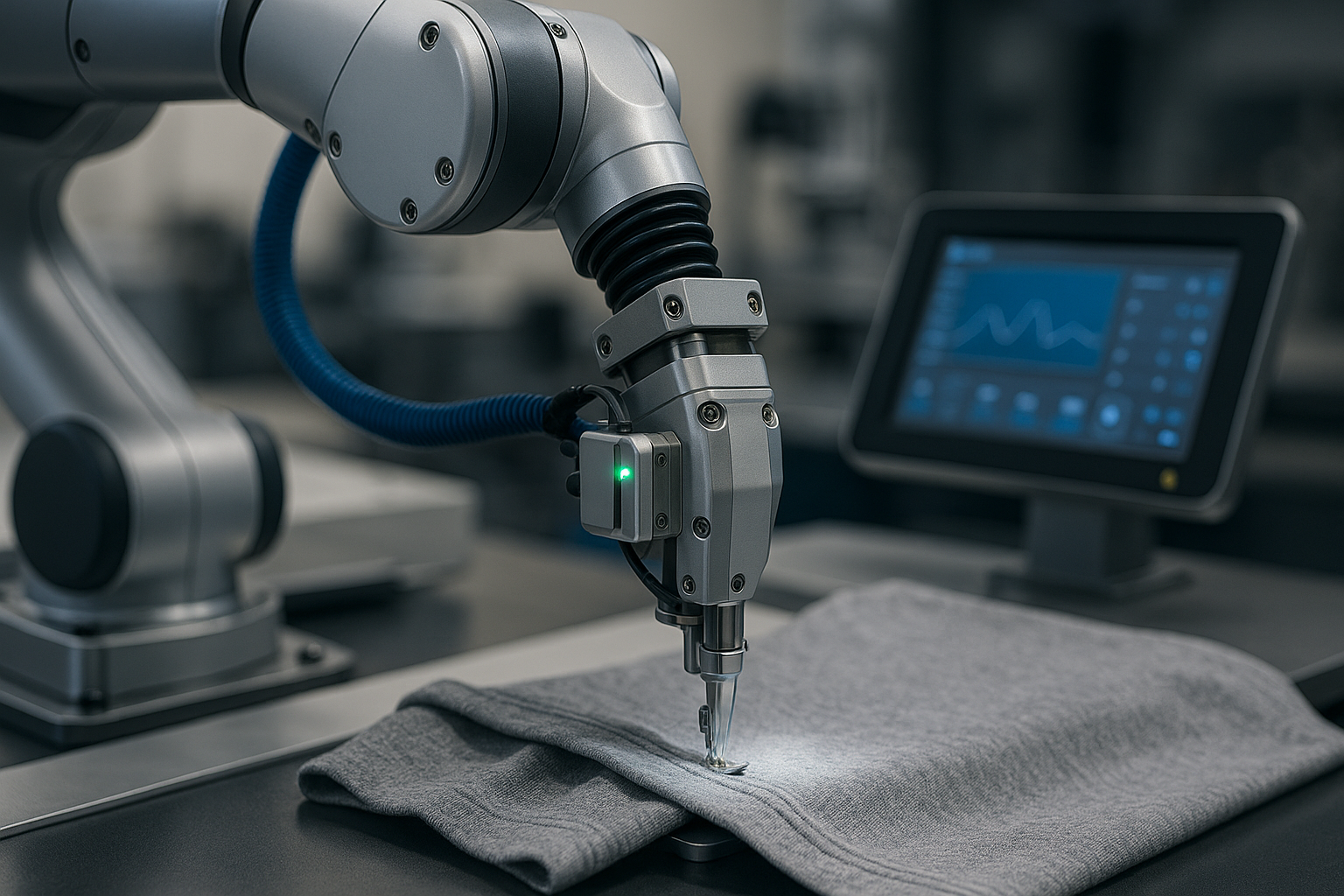

At the heart of robotic sewing lies the vision of automated precision: machines that can stitch garments with minimal human intervention while maintaining consistency, speed, and quality. In theory, automation reduces:

- Labor dependency in a tight-skilled labor market

- Human error, especially in quality-sensitive segments

- Lead times, aligning with fast fashion and just-in-time production

However, in practice, the implementation of robotic sewing is neither universal nor equally beneficial across all product types or production contexts. ROI varies significantly based on garment complexity, production volume, and integration capabilities.

Breaking Down the Investment

Initial Capital Expenditure (CapEx):

- A fully automated robotic sewing unit (e.g., from SoftWear Automation or Sewbotics) can cost between $100,000 to $350,000.

- Semi-automated modular workstations, like programmable sewing arms or edge-alignment robots, range from $15,000 to $60,000 per station.

Integration and Training:

- Additional costs include integration with ERP/MES systems, technician training, factory floor modification, and downtime during the learning curve.

Operational Costs:

- Electricity consumption, preventive maintenance, and consumables like sensors or robotic fingers need to be factored into Total Cost of Ownership (TCO).

Where ROI Makes Sense

✔️ T-Shirts and Basic Knits (High Volume, Low Complexity)

The sweet spot for robotic sewing lies in high-volume, low-skill garments — think T-shirts, briefs, or socks.

Why It Works:

- Minimal panel variation and seam complexity

- Easily programmable repetitive tasks (e.g., sleeve attach, hem folding)

- Large production batches amortize CapEx faster

ROI Snapshot:

A robotic T-shirt sewing line operating 24/7 can reduce labor costs by up to 60%, and recover the investment within 18–24 months in high-wage countries like the U.S. or Germany.

Case Example:

SoftWear Automation’s T-shirt sewbot platform, tested in Atlanta, reported production speeds of 1 shirt every 22 seconds, with quality metrics matching or exceeding human benchmarks.

✔️ Factories in High-Wage or Compliance-Intensive Zones

In countries with high labor costs or tight compliance regulations, automation improves not only cost efficiency but also audit readiness.

Strategic Gains:

- Reduced worker fatigue and injury risks (especially in repetitive strain tasks)

- Enhanced traceability and quality tracking

- More stable operations in volatile labor markets

✔️ Seam-Specific Automation (Instead of Full Garment)

Full-garment automation may be elusive for now, but partial robotic integration (seam or function-specific) offers measurable ROI.

High-ROI Applications:

- Automated bartack machines for belt loops or pockets

- Elastic waist attach modules with tension sensors

- Collar setting or cuff pressing modules with robotic feeders

Financial Insight:

Adding a $20,000 robotic waistband attachment unit can reduce manpower by 2 operators and improve cycle time by 25%, resulting in ROI in 12–18 months for mid-scale factories.

Where ROI Falls Short

❌ High-Complexity Garments (e.g., Jackets, Dresses, Denim Tops)

Precision handling of varied fabrics, variable seam directions, or intricate styling elements remains a challenge for full automation. Garments that require:

- Drape control

- Manual folding or pleating

- Multi-layer sewing with shifting fabric densities

…still rely heavily on human dexterity.

Insight:

A blazer may involve 80+ operations, many requiring nuanced handling. Attempting to automate these fully often leads to low utilization of expensive robotic units, diminishing ROI.

❌ Low-Wage Manufacturing Hubs

In regions like Bangladesh, Ethiopia, or Myanmar where labor costs remain low, the labor substitution advantage is minimal. ROI may take 5–7 years, often outpaced by labor turnover and operational reconfiguration needs.

However, these regions could benefit from automation in finishing and quality inspection, which adds value without displacing jobs drastically.

Strategic Metrics to Evaluate ROI

To go beyond pure financial metrics, ROI in robotic sewing should also be evaluated using:

| Metric | Description |

|---|---|

| Cost per Garment (CPG) | Total operating cost divided by units produced |

| OEE (Overall Equipment Effectiveness) | Measures machine availability, performance, and quality output |

| Uptime % | Indicates machine reliability and maintenance efficiency |

| Defect Rate Reduction | Tracks improvement in quality consistency |

| Time-to-Market | Measures acceleration in delivery lead times |

The Hybrid Model: Human + Machine Collaboration

The future of sewing isn’t about replacing workers, but augmenting them. A hybrid workstation where operators handle fabric alignment and machines execute precision stitching can deliver:

- Faster learning curves

- Flexible batch runs

- Lower CapEx with faster ROI

Companies like Juki, Durkopp Adler, and Pegasus are leading this hybrid shift with IoT-embedded smart machines, touchless foot control, and AI-assisted stitch programs.

Policy and Brand Push: ROI Beyond the Factory

Several brands and buyers are incentivizing automation by offering:

- Volume commitments to justify CapEx

- Shared investment models

- Sustainability-linked sourcing premiums (automation reduces waste, rework, and energy)

Governments in Vietnam, China, and Indonesia are also offering automation subsidies or tax breaks to accelerate smart factory adoption.

Conclusion: Robotic ROI Is About Fit, Not Fantasy

Robotic sewing delivers strong ROI when the product type, volume, and labor context align. It’s not about full automation of fashion production today, but about precision targeting of repetitive, high-waste, or high-risk tasks.

In the long term, factories that build modular, scalable automation ecosystems — combining robotics, AI, and operator expertise — will lead the SPACE (Sustainability, Precision, Automation, Circularity, Energy) transformation of textile and apparel manufacturing.