Freudenberg Performance Materials, a leading global supplier of technical textiles, will exhibit for the first time at CAMX 2025 in Orlando, Florida, from September 9-11. The company’s participation marks a strong commitment to supporting the North American composites industry. Freudenberg will present its high-performance surfacing veils, flow media, and spacers, with experts available at booth D69 to engage with attendees.

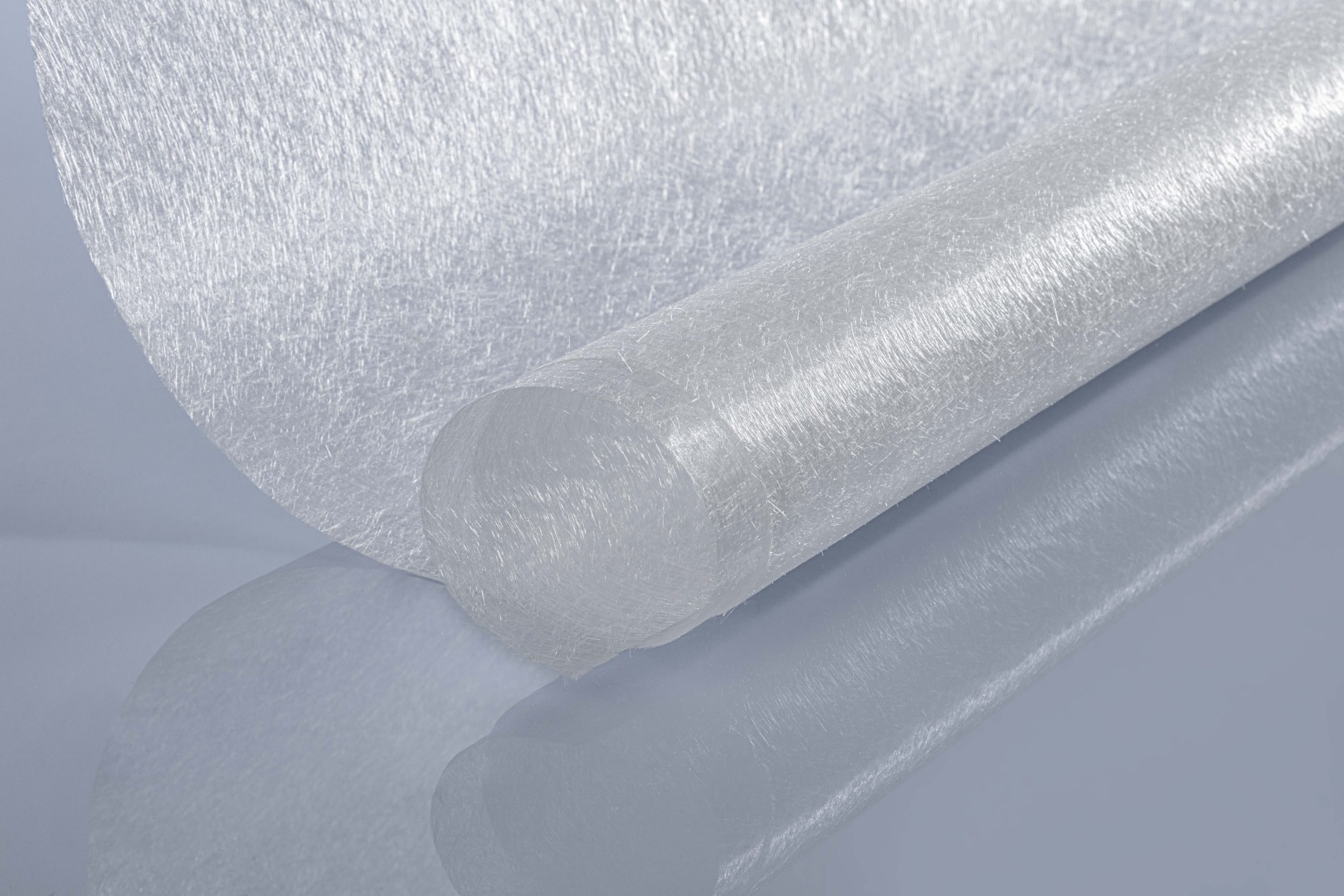

Freudenberg’s surfacing veils are crucial for Fiber Reinforced Polymer (FRP) components. They deliver enhanced abrasion resistance and corrosion protection, which are essential in maintaining the integrity of molded parts over time. These veils ensure longevity in applications where environmental stressors, such as UV exposure and moisture, can weaken materials. By extending the lifespan of products, Freudenberg’s surfacing veils provide reliability in critical industries like automotive, construction, and infrastructure.

In addition to surfacing veils, Freudenberg offers a versatile portfolio of nonwoven materials. These include advanced composites made from glass, PAN, and PET, designed for use in various applications. For example, they are used in anti-corrosive layers for piping and tank construction and in UV-resistant facade panels. The high-performance materials improve product durability by providing essential features like smooth surfaces, abrasion resistance, and mechanical strength, which are vital for withstanding environmental challenges.

One of the highlights at the Freudenberg booth will be the 3D polymer filaments from Enka®Solutions. These filaments optimize resin infusion and foam injection molding processes. Enka®Solutions flow media and spacers are designed for use in composite manufacturing processes like vacuum-assisted resin transfer molding (VARTM) and resin transfer molding (RTM). The 3D entangled polymer filaments in Enka®Solutions products enable improved bonding, minimize defects and wrinkles, and ensure complete wetting of internal structures.

Visitors to CAMX 2025 will have the chance to explore these advanced solutions and discuss how Freudenberg’s products can enhance manufacturing efficiency and product quality in composite production. Freudenberg’s experts will be on hand to demonstrate how their surfacing veils and flow media can help companies meet the highest standards in composite manufacturing.