The textile industry is confronted with an urgent challenge, massive amounts of textile waste accumulating globally, straining the environment and resources. A recent Boston Consulting Group (BCG) report sketches a hopeful path: textile recycling rates climbing above 30%, generating new fibers with a raw material value worth more than $50 billion and creating approximately 180,000 new jobs. Esteemed brands like Adidas, New Balance, and PUMA are recognized for their investments in textile-to-textile recycling, positioning themselves at the forefront of what could become an industry-wide transition.

There are some daunting barriers beneath these glossy forecasts that cast shadows over the industry’s aspirational path.

The Cost Conundrum

Despite growing environmental enthusiasm, recycled textiles remain a tough sell economically. Recycled polyester, for example, can cost up to twice as much as its virgin counterpart—a result of mature global supply chains optimized for virgin materials, subsidies, and the externalization of environmental costs. BCG itself acknowledges that brands have little financial incentive to choose recycled options without regulatory intervention. As long as the price gap persists, companies are likely to default to cheaper, less sustainable materials.

Infrastructure: The Missing Trillion-Dollar Link

Mass textile recycling is a logistical marathon, not a sprint. The industry generates vast volumes of waste—120 million metric tons annually, with projections climbing even higher. Most current systems are built for resale, not recycling, relying on manual sorting that struggles to keep up. To shift toward large-scale recycling would require trillions in capital for developing collection networks, advanced sorting, and chemical or molecular processing facilities. This crucial investment hurdle is often glossed over in visionary consultant reports.

Systemic Resistance: The Linear Model’s Iron Grip

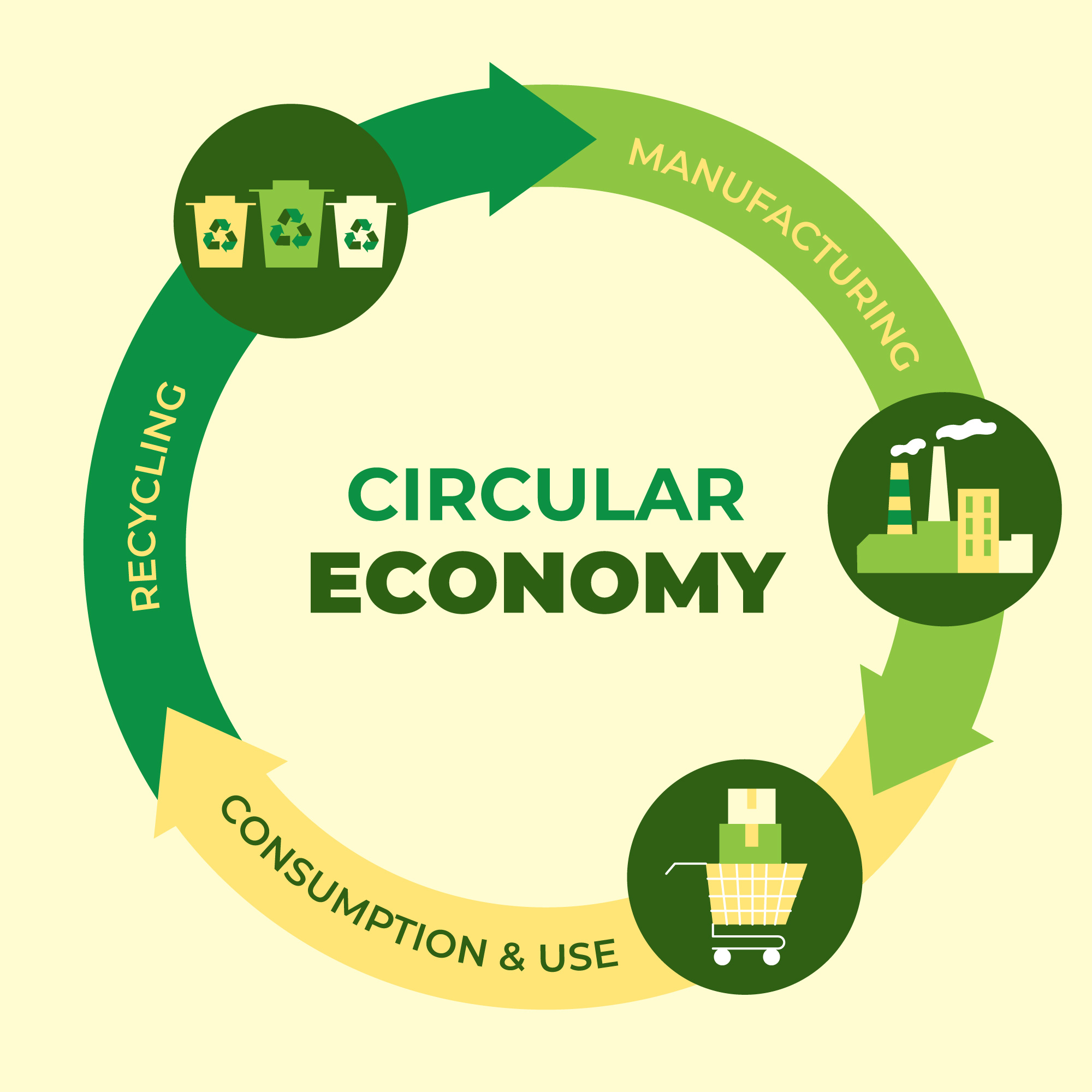

Systemic resistance embedded within the industry further complicates progress. The prevailing linear model—make, sell, discard—continues to benefit key actors entrenched in traditional business frameworks. These stakeholders are likely to resist changes that increase costs or require new responsibilities, such as Extended Producer Responsibility (EPR) regulations. Without policy mandates or enforced financial accountability for waste and recycling, systemic change remains difficult to achieve. The existing system’s inertia, shaped by economic interests and regulatory gaps, challenges the adoption of circular business models.

While BCG’s vision presents a road map for a circular textile economy, translating it into reality requires less focus on narrative and more commitment to tackling the unglamorous barriers: recalibrating economic incentives, mobilizing massive infrastructure investment, and restructuring the rules of the game. That means specific policy interventions—such as mandatory recycled content and EPR schemes—as well as transparent accounting of the true costs and limits of recycling.

The future of textile recycling—and fashion’s sustainability narrative will be shaped not only by brand PR and consultant optimism but by the messy, collaborative, and at times uncomfortable work of building a system that makes circularity practical, profitable, and fair.